|

Hot VW's - September 2011 - Crank Fired! A look at CB Performance's new digital ignition system

Crank

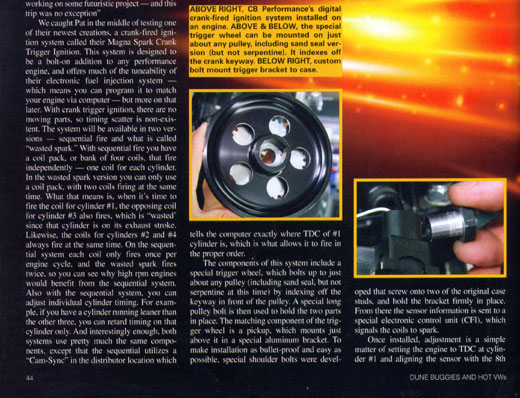

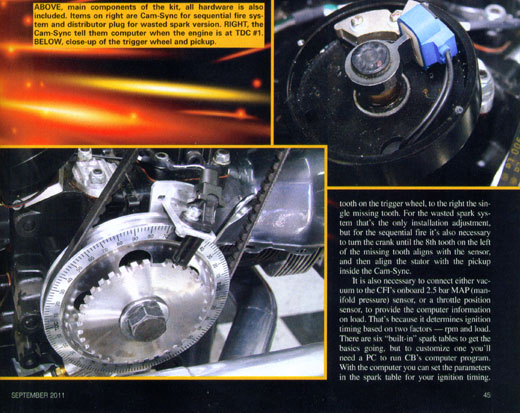

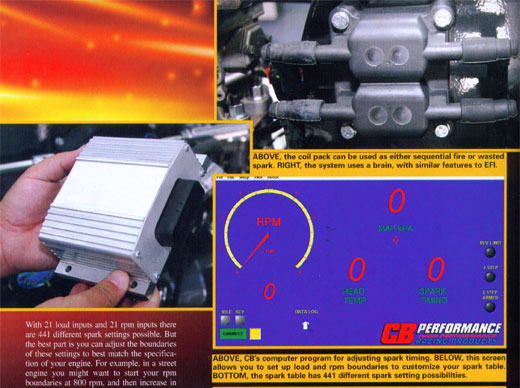

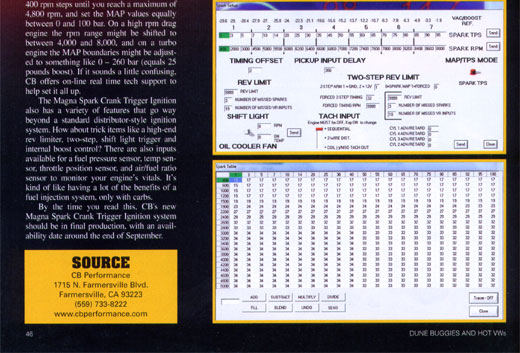

Fired! BY BRUCE SIMURDA One question we often get asked here at Hot VWs magazine is, "What's new in our industry?" And lately, the question has been easy to answer, with a variety of new products coming onto the market, such as the high performance pedal parts high-lighted last issue. This month, we took a drive up to CB Performance in Farmersville, California to see what they had in the works in their R&D department. If there is one thing you can count on, it's the CB crew working on some futuristic project - and this trip was no exception" We caught them in the middle of testing one of their newest creations, a crank-fired ignition system called their Magna Spark Crank Trigger Ignition System. This system is designed to be a bolt-on addition to any performance engine, and offers much of the tuneability of their electronic fuel injection system - which means you can program it to match your engine via computer - but more on that later. With crank trigger ignition, there are no moving parts, so timing scatter is non-existent. The system will be available in two versions - sequential fire and what is called "wasted spark." With sequential fire you have a coil pack, or bank of four coils, that fire independently - one coil for each cylinder. In the wasted spark version you can only use a coil pack, with two coils firing at the same time. What that means is, when it's time to fire the coil for cylinder #1, the opposing coil for cylinder #3 also fires, which is "wasted" since that cylinder is on its exhaust stroke. Likewise, the coils for cylinders #2 and #4 always fire at the same time. On the sequential system each coil only fires once per engine cycle, and the wasted spark fires twice, so you can see why high rpm engines would benefit from the sequential system. Also with the sequential system, you can adjust individual cylinder timing. For example, if you have a cylinder running leaner than the other three, you can retard timing on that cylinder only. And interestingly enough, both systems use pretty much the same components, except that the sequential utilizes a "Cam-Sync" in the distributor location which tells the computer exactly where TDC of #1 cylinder is, which is what allows it to fire in the proper order. The components of this system include a special trigger wheel, which bolts up to just about any pulley (including sand seal, but not serpentine at this time) by indexing off the keyway in front of the pulley. A special long pulley bolt is then used to hold the two parts in place. The matching component of the trigger wheel is a pickup, which mounts just above it in a special aluminum bracket. To make installation as bulletproof and easy as possible, special shoulder bolts were developed that screw onto two of the original case studs, and hold the bracket firmly in place. From there the sensor information is sent to a special electronic control unit (CFI), which signals the coils to spark. Once installed, adjustment is a simple matter of setting the engine to TDC at cylinder #1 and aligning the sensor with the 8th tooth on the trigger wheel, to the right [of] the single missing tooth. For the wasted spark system that's the only installation adjustment, but for the sequential fire it's also necessary to turn the crank until the 8th tooth on the left of the missing tooth aligns with the sensor, and then align the stator with the pickup inside the Cam-Sync. It is also necessary to connect either vacuum to the CFI's onboard 2.5 bar MAP (manifold pressure) sensor, or a throttle position sensor, to provide the computer information on load. That's because it determines ignition timing based on two factors - rpm and load. There are six "built-in" spark tables to get the basics going, but to customize one you'll need a PC to run CB's computer program. With the computer you can set the parameters in the spark table for your ignition timing. With 21 load inputs and 21 rpm inputs there are 441 different spark settings possible. But the best part is you can adjust the boundaries of these settings to best match the specification of your engine. For example, in a street engine you might want to start your rpm boundaries at 800 rpm, and then increase in 400 rpm steps until you reach a maximum of 4,800 rpm, and set the MAP values equally between 0 and 100 bar. On a high rpm drag engine the rpm range might be shifted to between 4,000 and 8,000, and on a turbo engine the MAP boundaries might be adjusted to something like 0 - 260 bar (equals 25 pounds boost). If it sounds a little confusing, CB offers on-line real time tech support to help set it all up. The Magna Spark Crank Trigger Ignition also has a variety of features that go way beyond a standard distributor-style ignition system. How about trick items like a high-end rev limiter, two-step, shift light trigger and internal boost control! There are also inputs available for a fuel pressure sensor, temp sensor, throttle position sensor, and air/fuel ratio sensor to monitor your engine's vitals. It's kind of like having a lot of the benefits of a fuel injection system, only with carbs. By the time you read this, CB's new Magna Spark Crank Trigger Ignition system should be in final production, with an availability date around the end of September. |