|

Hot VW's - October 2005 - Setting Rocker Geometry CB Performance shows you how to keep your arms as straight as possible.

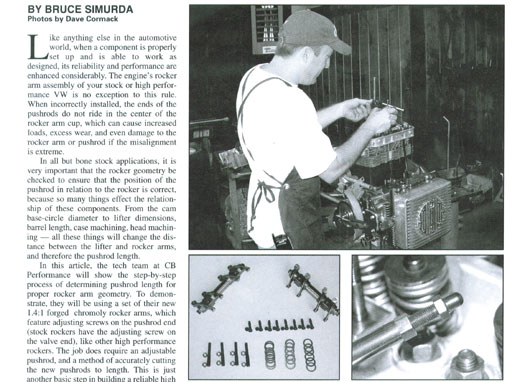

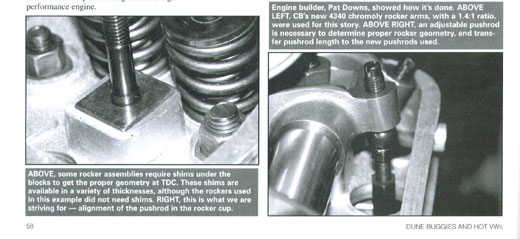

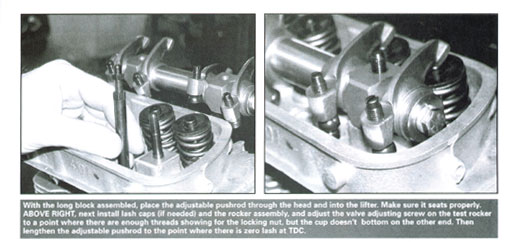

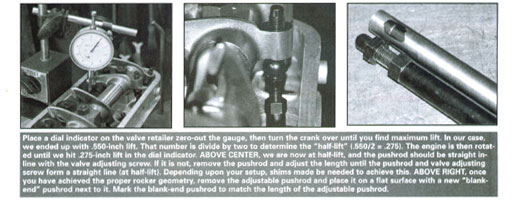

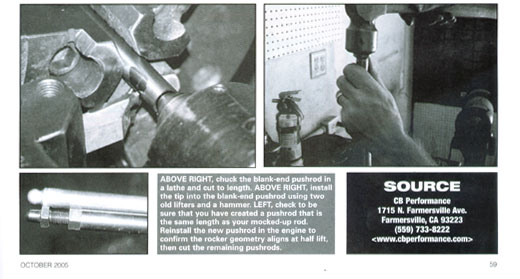

SETTING ROCKER GEOMETRY CB Performance shows you how to keep your arms as straight as possible. BY BRUCE SIMURDA Like anything else in the automotive world, when a component is properly set up and is able to work as designed, its reliability and performance are enhanced considerably. The engine's rocker arm assembly of your stock or high performance VW is no exception to this rule. When incorrectly installed, the ends of the pushrods do not ride in the center of the rocker arm cup, which can cause increased loads, excess wear, and even damage to the rocker arm or pushrod if the misalignment is extreme. In all but bone stock applications, it is very important that the rocker geometry be checked to ensure that the position of the pushrod in relation to the rocker is correct, because so many things effect the relationship of these components. From the cam base-circle diameter to lifter dimensions, barrel length, case machining, head machining - all these things will change the distance between the lifter and rocker arms, and therefore the pushrod length. In this article, the tech team at CB Performance will show the step-by-step process of determining pushrod length for proper rocker arm geometry. To demonstrate, they will be using a set of their new 1.4:1 forged chromoly rocker arms, which feature adjusting screws on the pushrod end (stock rockers have the adjusting screw on the valve end), like other high performance rockers. The job does require an adjustable pushrod, and a method of accurately cutting the new pushrods to length. This is just another basic step in building a reliable high performance engine. |