VW Trends - November 1996 - Back to Basics - Camshaft Technology   Back to Basics - Camshaft TechnologyBy Richard Holdener (November 1996 - VW Trends)

Every once in a while, we forget that a great many of our readers might be looking at the subject of a technical article for the very first time. Sure, a lot of you have rebuilt flat fours in your backyard, but believe it or not, there are a lot of new VW owners who have no idea what a valve spring is, let alone what it does. Most of the time, we (editors) go off happily down the road with our stories, content in the knowledge that we have informed a number of readers on the merits of porting, dual carbs, or high compression, completely oblivious to the fact that we may have just alienated a great many more readers who haven't the faintest idea what we are talking about. At one point or another, everyone reading this book was just like you, even us. We don't know of anyone who was ever blessed with absolute automotive knowledge. Everyone had to start from the beginning. So, we thought it might be a good idea to take a giant step back and take a broad look at one of the more complex systems in VW motors, namely the camshaft and related components. For many, this will be nothing more than a refresher course, but for some it will be an eye opening experience that might shed some light on a dark, mysterious subject.

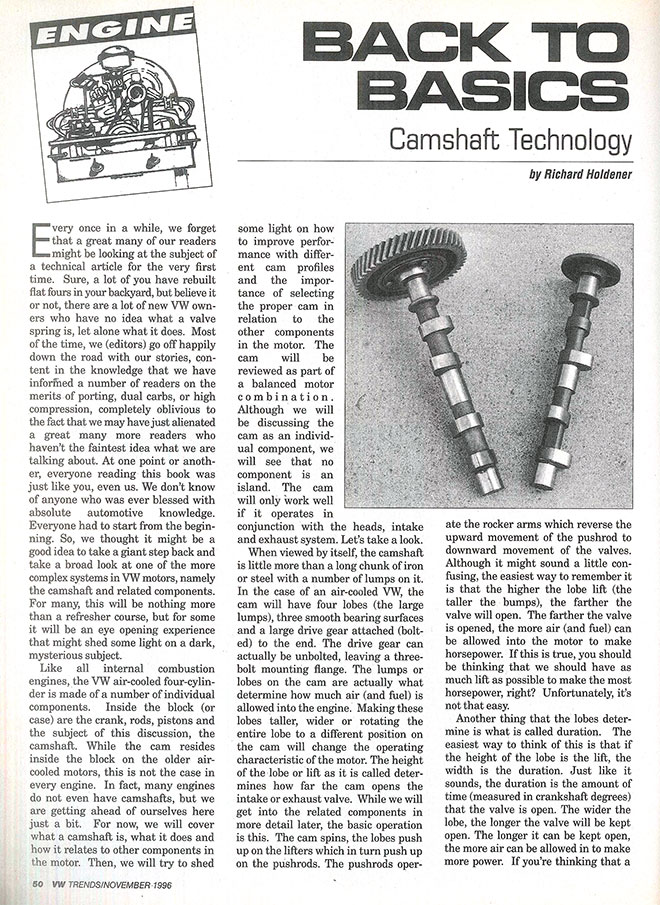

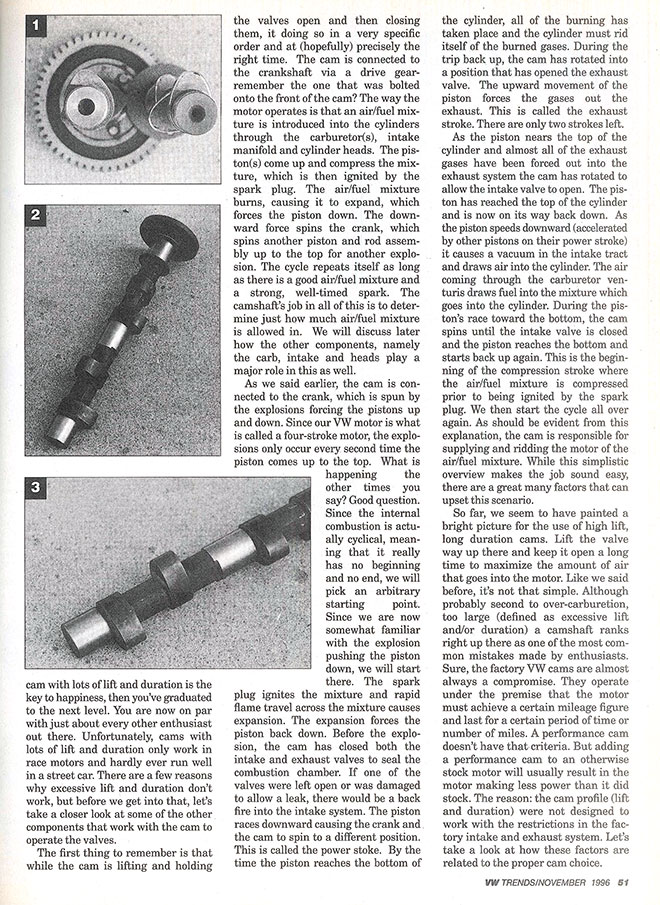

Like all internal combustion engines, the VW air-cooled four-cylinder is made of a number of individual components. Inside the block (or case) are the crank, rods, pistons and the subject of this discussion, the camshaft. While the cam resides inside the block on the older air-cooled motors, this is not the case in every engine. In fact, many engines do not even have camshafts, but we are getting ahead of ourselves here just a bit. For now, we will cover what a camshaft is, what it does and how it relates to other components in the motor. Then, we will try to shed some light on how to improve performance with different cam profiles and the importance of selecting the proper cam in relation to the other components in the motor. The cam will be reviewed as part of a balanced motor combination. Although we will be discussing the cam as an individual component, we will see that no component is an inland. The cam will only work well if it operates in conjunction with the heads, intake and exhaust system. Let's take a look. When viewed by itself, the camshaft is little more than a long chunk of iron or steel with a number of lumps on it. In the case of an air-cooled VW, the cam will have four lobes (the large lumps), three smooth bearing surfaces and a large drive gear attached (bolted) to the end. The drive gear can actually be unbolted, leaving a three-bolt mounting flange. The lumps or lobes on the cam are actually what determine how much air (and fuel) is allowed into the engine. Making these lobes taller, wider or rotating the entire lobe to a different position on the cam will change the operating characteristic of the motor. The height of the lobe or lift as it is called determined how far the cam opens the intake or exhaust valve. While we will get into the related components in more detail later, the basic operation is this. The cam spins, the lobes push up on the lifters which in turn push up on the pushrods. The pushrods operate the rocker arms which reverse the upward movement of the pushrod to downward movement of the valves. Although it might sounds a little confusing, the easiest way to remember it is that the higher the lobe lift (the taller the bumps), the farther the valve is opened, the more air (and fuel) can be allowed into the motor to make horsepower. If this is true, you should be thinking that we should have as much lift as possible to make the most horsepower, right? Unfortunately, it's not that easy. Another thing that the lobes determine is what is called duration. The easiest way to the think of this is that if the height of the lobe is the lift, the width is the duration. Just like it sounds, the duration is the amount of time (measure in crankshaft degrees) that the valve is open. The wider the lobe, the longer the valve will be kept open. The longer it can be kept open, the more air can be allowed in to make more power. If you're thinking that a cam with lots of lift and duration is the key to happiness, then you've graduated to the next level. You are now on par with just about every other enthusiast out there. Unfortunately, cams with lots of lift and duration only work in race motors and hardly ever run well in a street car. There are a few reasons why excessive lift and duration don't work, but before we get into that, let's take a closer look at some of the other components that work with the cam to operate the valves. The first thing to remember is that while the cam is lifting and holding the valve open and then closing them, it doing so in a very specific order and at (hopefully) precisely the right time. The cam is connected to the crankshaft via a drive gear - remember the one that was bolted onto the front of the cam? The way the motor operates is that an air/fuel mixture is introduced into the cylinders through the carburetor(s), intake manifold and cylinder heads. The piston(s) come up and compress the mixture, which is then ignited by the spark plug. The air/fuel mixture burns, causing it to expand, which forces the piston down. The downward force spins the crank, which spins another piston and rod assembly up to the top for another explosion. The cycle repeats itself as long as there is a good air/fuel mixture and a strong, well-timed spark. The camshaft's job in all of this is to determine just how much air/fuel mixture is allowed in. We will discuss later how the other components, namely the carb, intake and heads play a major role in this as well. As we said earlier, the cam is connected to the crank, which is spun by the explosions forcing the pistons up and down. Since our VW motor is what is called a four-stroke motor, the explosions only occur every second time the piston comes up to the top. What is happening the other times you say? Good question. Since the internal combustion is actually cyclical, meaning that it really has no beginning and no end, we will pick an arbitrary starting point. Since we are now somewhat familiar with the explosion pushing the piston down, we will start there. The spark plug ignites the mixture and rapid flame travel across the mixture causes expansion. The expansion forces the piston back down. Before the explosion, the cam has closed both the intake and exhaust valves to seal the combustion chamber. If one of the valves were left open or was damaged to allow a leak, there would be a back fire into the intake system. The piston races downward causing the crank and the cam to spin to a different position. This is called the power stroke. By the time the piston reaches the bottom of the cylinder, all of the burning has taken place and the cylinder must rid itself of the burned gases. During the trip back up, the cam has rotated into a position that has opened the exhaust valve. The upward movement of the piston forces the gases out the exhaust. The is called the exhaust stroke. There are only two strokes left. As the piston nears the top of the cylinder and almost all of the exhaust gases have been forced out into the exhaust system the cam has rotated to allow the intake valve to open. The piston has reached the top of the cylinder and is now on its way back down. As the piston speeds downward (accelerated by other pistons on their power stroke) it causes a vacuum in the intake tract and draws air into the cylinder. The air coming through the carburetor venturis draws fuel into the mixture which goes into the cylinder. During the piston's race toward the bottom, the cam spins until the intake valve is closed and the piston reaches the bottom and starts back up again. This is the beginning of the compression stroke where the air/fuel mixture is compressed prior to being ignited by the spark plug. We then start the cycle all over again. As should be evident from this explanation, the cam is responsible for supplying and ridding the motor of the air/fuel mixture. While this simplistic overview makes the job sound easy, there are a great many factors that can upset this scenario. So far, we seem to have painted a bright picture for the use of high lift, long duration cams. Lift the valve way up there and keep it open a long time to maximize the amount of air that goes into the motor. Like we said before, it's not that simple. Although probably second to over-carburetion, too large (defined as excessive lift an/or duration) a camshaft ranks right up there as one of the most common mistakes made by enthusiasts. Sure, the factory VW cams are almost always a compromise. They operate under the premise that the motor must achieve a certain mileage figure and last for a certain period of time or number of miles. A performance cam doesn't have that criteria. But adding a performance cam to an otherwise stock motor will usually result in the motor making less power than it did stock. The reason: the cam profile (lift and duration) were not designed to work with the restrictions in the factory intake and exhaust system. Let's take a look at how these factors are related to the proper cam choice. Perhaps the easiest way to think about a camshaft is in terms of the desired powerband of the motor. Let's say that a stock cam is designed to operate most efficiently between 1700 rpm and 4000 rpm. A lot of development went into the rest of the motor to make it compatible with that cam and vice versa. The intake manifold port size and runner length have been optimized to work most efficiently in the same rpm range, likewise for the compression, exhaust system and carburetion. Changing one thing, say the camshaft, will usually have a negative effect because now all of the major components are no longer operating efficiently together. The cam wants to make power 1000 rpm higher, but the carb, intake, heads and exhaust were never designed to run that high, not to mention the stock (weak) valve springs. The end result will be that the motor no longer makes as much power as it did in the normal operating range, and can't rev to make power where the new cam wants to run. The key is to match the components to the cam. If the cam is designed to make peak power at 5000 rpm, then make sure there is enough carburetion to feed the new rpm level. Ditto for the intake manifold. Maybe a single carb won't feed the new power level and the cam needs a set of dual Webers. With the cam, intake and carb working together, is the head going to flow enough air for the new components. What about the exhaust? This brings up an interesting point about head flow and its relationship to the camshaft. Most camshaft manufacturers will agree that increasing duration increases the rpm at which the motor wants to make peak power. The added power at the top end of the rpm scale unfortunately reduces the power at the bottom. A long duration cam reduces the signal to the carburetor, making the motor much less responsive and generally a bear to drive on the street. This is why excessive duration is not desirable on the street. There seems to be some confusion about lift figure though. Adding lift will not always increase the rpm at which the motor makes peak power. The problem with adding lift is that the heads may not flow very well at the higher lift figures. A quick lesson is in order here. Cylinder heads are air-flow tested on an air flow bench at different valve lift figures. This works out well as it is important to see how much air the head will flow given a certain lift cam. Air flow tests generally begin at .050" lift and work their way up to and beyond .600" lift, which most street cams coming in at less than .500" lift. Adding a cam with .500" lift will be of no benefit if the heads do not flow well past .400" lift. All the lift in the world won't make the heads flow any better, they will need to be ported to work with the new cam. This goes right along with our discussion on how important it is to have all of the components work together as a team. Now that you have a basic understanding of camshafts, we feel confident in giving you some rough guidelines about performance cams. Remember, while we are making some suggestions about cams here, the key is to have the cam work with the rest of the components in the motor. As we mentioned earlier, the valve lift figures for a street cam should be kept somewhere near .400" lift, with some down around .350" lift. There are a number of aftermarket sources for these cams and the manufacturers will be able to recommend other components for use with the performance cam. The reason for the relatively small lift figure is that VW heads are not known for their high-lift flow figures. Another reason to keep lift down is that the greater the lift, the more chance you have of running into a piston to valve interference problem. This is where the valve lifts so high (toward to piston) that the two actually come in contact, not a good thing! Duration figures should be kept under 300 degrees for street/strip motors and most hot street motors should run cams with less than 290 degrees of advertised duration. Again, contact your supplier for exact cam specs for your application. While there was no way we could cover every aspect of camshaft technology, the basics covered here should get you on the fast track. Remember, when it comes to cams, sometimes less is more. |