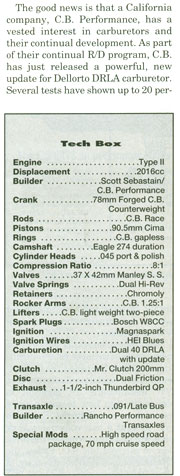

VW Trends - January 1996 - Dellorto DRLA Update

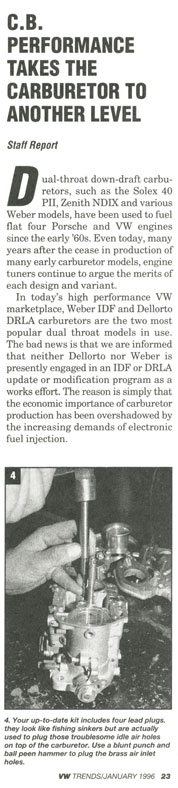

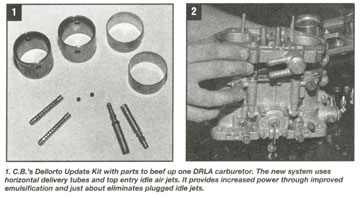

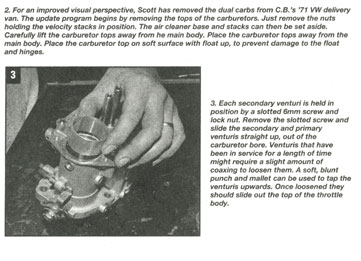

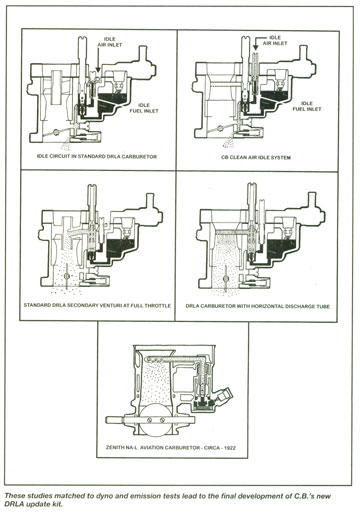

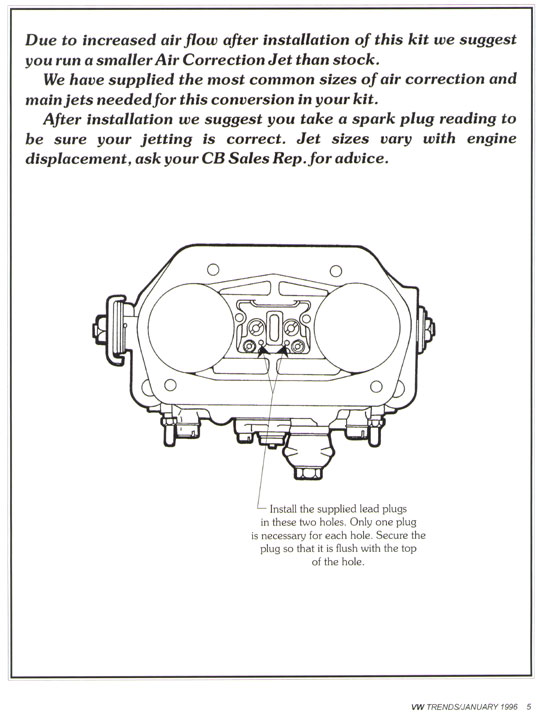

1. CB's Dellorto Update Kit with parts to beeg up one DRLA carburetor. The new system uses horizontal delivery tubes and top entry idel air jets. It provides increased power through improved emulsification and just about eliminates plugged idle jets. 1. For an improved visual perspective, Scott has removed the dual carbs from CB's '71 VW Delivery van. The update program begins by removing the tops of the carburetors. Just remove the nuts holding the velocity stacks in position. The air cleaner base and stacks can then be set aside. Carefully lift the carburetor tops away from the main body. Place the carburetor tops away from the main body. Place the carburetor top on soft surface with float up, to prevent damage to the float and hinges. 3. Each secondary venturi is held in position by a slotted 6mm screw and lock nut. Remove the slotted screw and slide the secondary and primary venturis straight up, out of the carburetor bore. Venturis that have been in service for a length of time might require a slight amount of coaxing to loosen them. A soft, blunt punch and mallet can be used to tap the venturis upwards. Once loosened they should slide out the top of the throttle body. 4. Your up-to-date kit includes four lead plugs, they look like fishing sinkers but are actually used to plug those troublesome idle air holes on top of the carburetor. Use a blast punch and ball peen hammer to plug the brass air inlet holes.

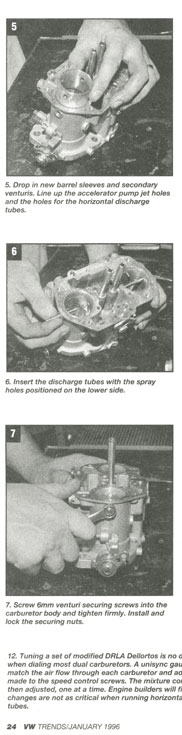

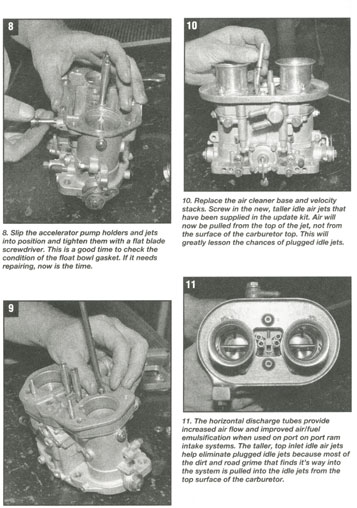

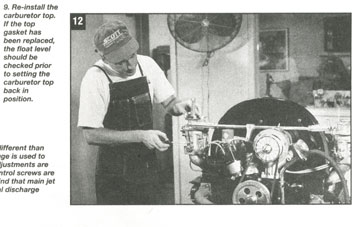

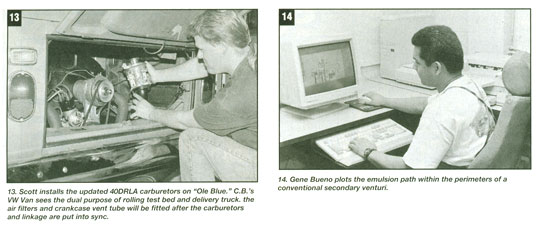

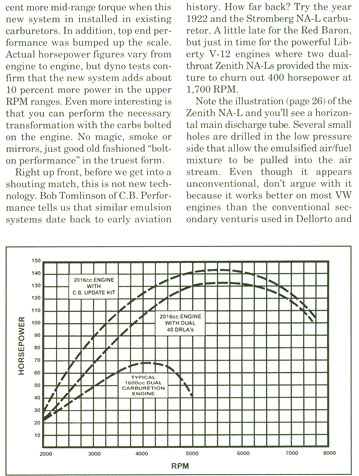

5. Drop in new barrel sleeves and secondary venturis. Line up the accelerator pump jet holes and the holes for the horizontal discharge tubes. 6. Insert the discharge tubes with the spray holes positioned on the lower side. 7. Screw 6mm venturi securing screws into the carburetor body and tighten firmly. Install and lock the securing studs. 8. Slip the accelerator pump holders and jets into position and tighten them with a flat blade screwdriver. This is a good time to check the condition of the float bowl gasket. If it needs repairing, now is the time. 9. Re-intall the carburetor top. If the top gasket has been replaced, the float level should be checked prior to setting the carburetor top back in position. 10. Replace the air cleaner base and velocity stacks. Screw in the new, taller idle air jets that have been supplied in the update kit. Air will now be pulled from the top of the jet, not from the surface of the carburetor top. This will greatly lesson the chances of plugged idle jets. 11. The horizontal discharge tubes provide increased air flow and improved air/fuel emulsification when used on port on port ram intake systems. The taller, top inlet idle air jets help eliminate plugged idle jets because most of the dirt and road grime that finds it's way into the system is pulled into the idle jets from the top surface of the carburetor. 12. Tuning a set of modified DRLA Dellortos is no different than when dialing most dual carburetors. A unisync gauge is used to match the air flow through each carburetor and and adjustments are made to the speed control screws. The mixture control screws are then adjusted, one at a time. Engine builders will find that main jet changes are not as critical when running horizontal discharge tubes. 13. Scott installs the updated 40DRLA carburetors on "Ole Blue" CB's VW Van sees the dual purpose of rolling test bed and delivery truck, the air filters and crankcase vent tube will be fitted after the carburetors and linkage are put into sync. 14. Gene Bueno plots the emulsion path within the perimeters of a conventional secondary venturi. Page 3

Page 4

Page 5

|

||||||||||||||||||||||