|

Hot VWs - September 2007 - Project Mileage Motor - Part 9 Ignition timing and carb jetting tests

Project

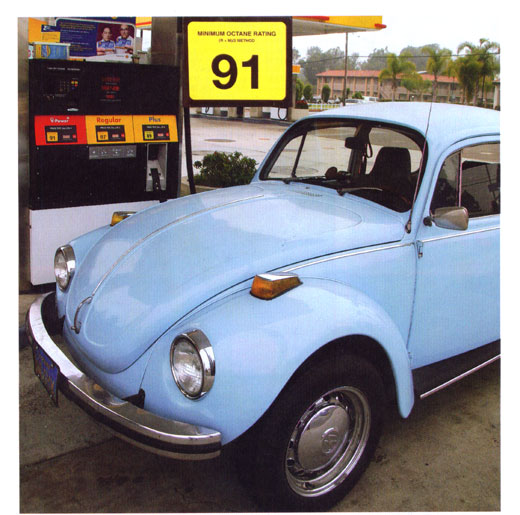

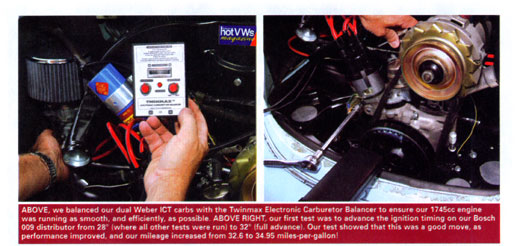

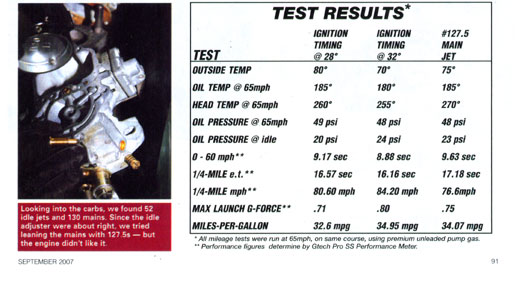

Mileage Motor BY BRUCE SIMURDA It's hard to believe that we're already on Part 9 of our ongoing series on building an engine that will deliver 35-40 miles-per-gallon from our air-cooled VW, which started way back in the November 2006 issue. If you remember, the basis of this project is a 1745cc mill that runs stock 85.5mm pistons and cylinders, but a longer 76mm stroker crankshaft, small valve dual-port heads, special mileage cam from CB Performance, and a lot of other components chosen to keep drag to a minimum, and hopefully improve mileage. Up to last month, we hadn't yet cracked the 30 mpg barrier, but the addition of a "freeway flyer" transaxle changed that. By allowing us to take advantage of the engine's fantastic torque curve, we were able to obtain 32.6 mpg on our last test run, which is a 100-mile jaunt down the freeway at 65 miles-per-hour. We should mention that all tests are run on the same course, and the car, a 1972 Super Beetle in stock trim, is refueled with the same premium pump gas - from the same pump - before and after every run to ensure repeatability. This month we're going to try two things - increasing the ignition timing, and leaning out the jets. But before doing that, we wanted to ensure that the carbs were perfectly balanced, so we used a Twinmax Electronic Carburetor Balancer to make the job a cinch. Basically, you simply connect one of two hoses at the bottom of the Twinmax to a vacuum port on each carb or manifold, adjust the electronic balance needle to zero, start the engine, and adjust the carbs until the balance needle reads zero. There is also a sensitivity adjuster for fine tuning, and the entire process makes balancing a snap, as you don't need to keep moving the balancer for one carb to the other after each adjustment. With that done, we proceeded to advance our timing. Up to this point, all tests were done with our Bosch 009 distributor at 28° full advance, but we bumped it up to 32° for this test, to see if we could squeeze a few more MPG's out of the fuel. Right off the bat we could tell that this was going to produce some good results, as the bottom end just felt stronger as well pulled away from the office. And the performance test, which is performed first, confirmed our optimism as the 0-60 mph time, 1/4-mile e.t., 1/4-mile mph, and even maximum G-force had improved across the board (see chart). Still not as good as with the stock geared transaxle was, mind you, but better than our previous results with the freeway flyer's tall gearing. With that, we hit the freeway and, after running our 100-mile course, we netted a best-ever 34.95 miles-per-gallon - just shy of our minimum goal of 35 mpg. With that good news, we pulled the carb tops off and discovered that they were equipped with 52 idle jets, and 130 mains. Since the idle adjusting screws were running just about perfect, at 2-1/2 turns out, we decided to leave them alone, but did decide to go down on the mains slightly, to 127.5s. Hopefully, the leaner mixture would sip less fuel. Unfortunately, it didn't quite work out that way. The performance test showed right away that the engine didn't like the leaner air-fuel mixture, and the mileage test run had the same result - a drop to 34.07 miles-per-gallon. Not a big drop mind you, but the head temp also appeared to be running somewhat hotter, so there was obviously no benefit from the change. Next month, we'll try a few more jetting changes, and perhaps a few unique products that promise to improve mileage, as we get ready to install a new fuel injection system from CB Performance in our search for 40 mpg! |