|

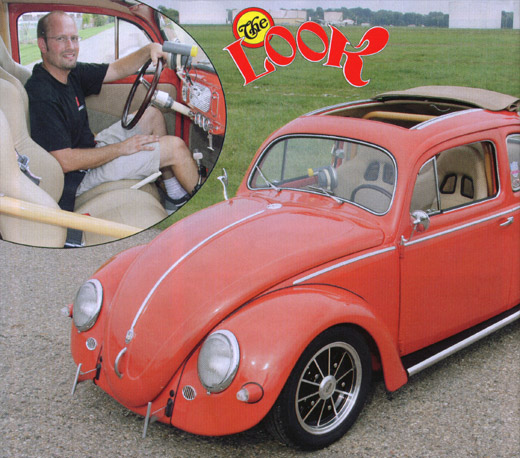

Hot VW's - January 2007 - Canadian Cruiser/Racer This beautiful '56 Oval Window is owned by Oakville, Ontario's Greg Stogren, runs a turbo/EFI 2387cc built by CB Performance, and is quite a quick looker on the street or drag strip

Canadian

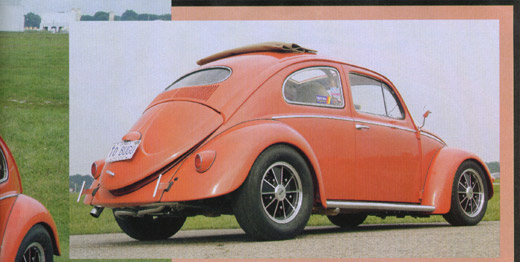

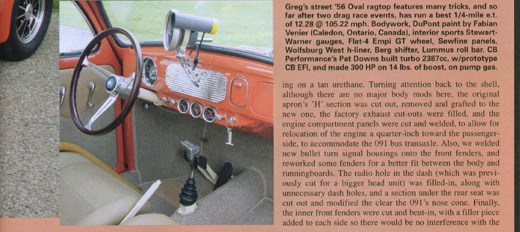

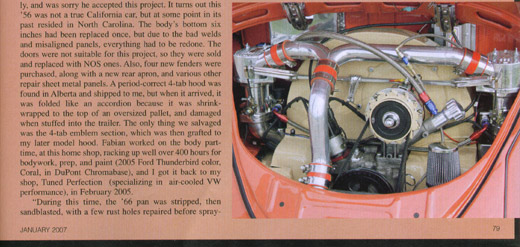

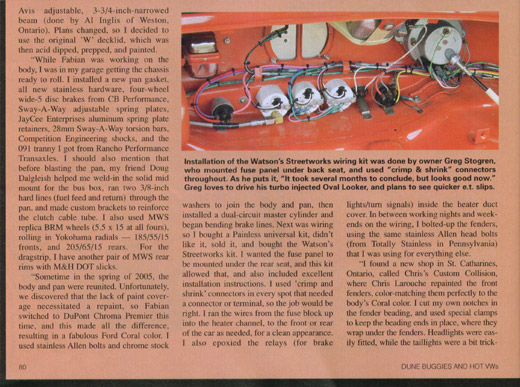

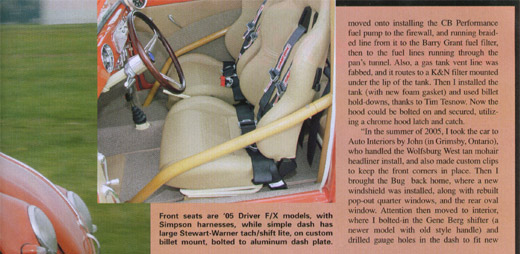

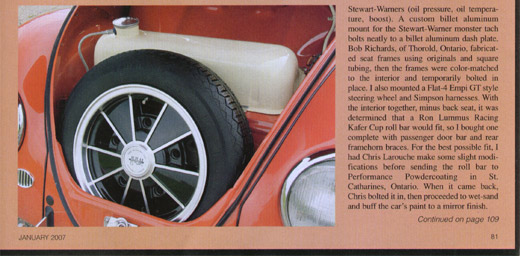

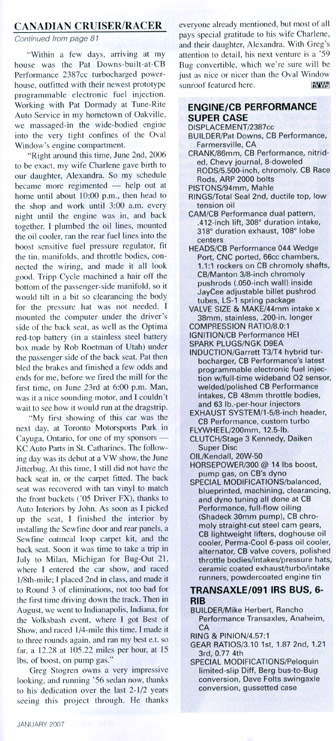

Cruiser/Racer BY ROBERT K. SMITH Oaksville, Ontario, Canada's Greg Stogren was hooked on VWs at the early age of 14, when he purchased his very first car, a Tamiya radio-controlled "Monster Beetle." A year later, he bought his first real car, a '73 Super Beetle, which turned out to be a pile, and was parted out, primarily due to heavy rust that no bodyman wanted any part of. Then came a "basket-case" project '68 Bug that was eventually put pack together, and by 1991, became a good looking showpiece of a street car that won awards. Over the next ten years, this same car saw upgrades like a 1776cc engine, and Kaption Audio stereo. Then in early 2003, Greg ordered a 2110cc engine from CB Performance (Farmersville, California), and air ride system from Air Lift Company, then shortly thereafter sold his Bug, and turned his attention to the '56 Oval Window featured here. In Greg's words, "I bought this car after seeing it for sale on eBay. It was located in Concord, California, and came with Flat 4 BRM style wheels, a dual Dellorto-carbed 1776cc engine, and Sewfine interior. The car did not meet reserve, so I struck a deal with the owner, and by November 2003, this Oval was in my garage; the auto transport carrier driver dropped it off, I took it for a two-minute drive around the block, then started taking it apart that winter. In June of '04, the body was acid-dipped, along with the doors, fenders, and hood; the decklid was not since i planned to use a fiberglass one. Then the body was delivered to Fabian Venier of Caledon, Ontario; he did not expect the prior repairs to be done so poorly, and was sorry that he accepted this project. It turns out this '56 was not a true California car, but at some point in its past resided in North Carolina. The body's bottom six inches had been replaced once, but due to the bad welds and misaligned panels, everything had to be redone. The doors were not suitable for this project, so they were sold and replaced with NOS ones. Also, four new fenders were purchased, along with a new rear apron, and various other repair sheet metal panels. A period-correct 4-tab hood was found in Alberta and shipped to me, but when it arrived, it was folded like an accordion because it was shrink-wrapped to the top of an oversized pallet, and damaged when stuffed into the trailer. The only thing we salvaged was the 4-tab emblem section, which was then grafted to my later model hood. Fabian worked on the body part-time, at this home shop, racking up well over 400 hours for bodywork, prep, and paint (2005 Ford Thunderbird color, Coral, in DuPont Chromabase), and i got it back to my shop, Tuned Perfection (specializing in air-cooled VW performance), in February 2005. "During this time, the '66 pan was stripped, then sandblasted, with a few rust holes repaired before spraying on a tan urethane. Turning attention back to the shell, although there are no major body mods here, the original apron's 'H' section was cut out, removed and grafted to the new one, the factory exhaust cut-outs were filled, and the engine compartment panels were cut and welded, to allow for relocation of the engine a quarter-inch toward the passenger side, to accommodate the 091 Bus Transaxle. Also, we welded new bullet turn signal housings onto the front fenders, and reworked some fenders for a better fit between the body and running boards. The radio hole in the dash (which was previously cut for a bigger head unit) was filled-in, along with unnecessary dash holes, and a section under the rear seat was cut out and modified to clear the 091's nose cone. Finally, the inner front fenders were cut and bent-in, with a filler piece added to each side so there would be no interference with the Avis adjustable, 3 3/4-inch-narrowed beam (done by Al Inglis of Weston, Ontario). Plans changed, so I decided to use the original 'W' decklid, which was then acid dipped, prepped, and painted. "While Fabian was working on the body, I was in my garage getting the chassis ready to roll. I installed a new pan gasket, all new stainless hardware, four-wheel wide-5 disc brakes from CB Performance, Sway-A-Way adjustable spring plates, JayCee Enterprises aluminum spring plate retainers, 28mm Sway-A-Way torsion bars, Competition Engineering shocks, and the 091 tranny I got from Rancho Performance Transaxles. I should also mention that before blasting the pan, my friend Doug Dalgleish helped me weld-in the solid mid mount for the bus box, ran two 3/8-inch hard lines (fuel feed and return) through the pan, and made custom brackets to reinforce the clutch cable tube. I also used MWS replica BRM wheels (5.5 x 15 at all fours), rolling in Yokohama radials - 185/55/15 fronts, and 205/65/15 rears. For the dragstrip, I have another pair of MWS rear rims with M&H DOT slicks. "Sometime in the spring of 2005, the body and pan were re-united. Unfortunately, we discovered that the lack of paint coverage necessitated a repaint, so Fabian switched to DuPont Chroma Premier this time, and this made all the difference, resulting in a fabulous Ford Coral color. I used stainless Allen bolts and chrome stock washers to join the body and pan, then installed a dual-circuit master cylinder and began bending brake lines. Next was wiring, so I bought a Painless universal kit, didn't like it, sold it, and bought the Watson's Streetworks kit. I wanted the fuse panel to be mounted under the rear seat, and this kit allowed that, and also included excellent installation instructions. I used 'crimp and shrink' connectors in every spot that needed a connector or terminal, so the job would be right. I ran the wires from the fuse block up into the heater channel, to the front or rear of the car as needed, for a clean appearance. I also epoxied the relays (for brake light/turn signals) inside the heater duct cover. In between working nights and weekends on the wiring, I bolted-up the fenders, using the same stainless Allen head bolts (from Totally Stainless in Pennsylvania) that I was using for everything else. "I found a new shop in St. Catharines, Ontario, called Chris's Custom Collision, where Chris Larouche repainted the front fenders, color-matching them perfectly to the body's Coral color. I cut my own notches in the fender beading, and used special clamps to keep the heading ends in place, where they wrap under the fenders. Headlights were easily fitted, while the taillights were a bit trickier. I had the holes filled in the rear fenders so that I could precisely locate the '56 taillights in the exact spots they were designed to be, and drilled new holes accordingly, then secured the taillight assemblies. Once the fenders were on, I installed front and rear custom-by-Craig Parks polished aluminum T-bars. I also found a Volvo reservoir to fit my master cylinder and installed it, along with a LineLoc and Wilwood proportioning valve. With the front brakes completely plumbed, I moved into installing the CB Performance fuel pump to the firewall, and running braided line from it to the Barry Grant fuel filter, then to the fuel lines running through the pan's tunnel. Also, a gas tank vent line was fabbed, and it routes to a K&N filter mounted under the lip of the tank. Then I installed the tank (with new foam gasket) and used billet hold-downs, thanks to Tim Tesnow. Now that hood could be bolted on and secured, utilizing a chrome hood latch and catch. "In the summertime of 2005, I took the car to Auto Interiors by John (in Grumsby, Ontario), who handled the Wolfsburg West tan mohair headliner install, and also made custom clips to keep the front comers in place. Then I brought the Bug back home, where a new windshield was installed, along with rebuilt pop-out quarter windows, and the rear oval window. Attentions then moved to interior, where I bolted-in the Gene Berg shifter (a newer model with old style handle) and drilled gauge holes in the dash to fit new Stewart-Warners (oil pressure, oil temperature, boost). A custom billet aluminum mount for the Stewart-Warner monster tach bolts neatly to a billet aluminum dash plate. Bob Richards, of Thorold, Ontario, fabricated scat frames using originals and square tubing, then the frames were color-matched to the interior and temporarily bolted in place. I also mounted a Flat-4 Empi GT style steering wheel and Simpson harnesses. With the interior together, minus back seat, it was determined that a Ron Lummus Racing Kafer Cup roll bar would fit, so I bought one complete with passenger door bar and rear framehorn braces. For the best possible fit, I had Chris Larouche make some slight modifications before sending the roll bar to Performance Powdercoating in St. Catharines, Ontario. When it came back, Chris bolts it it, then proceeded to wet-sand and buff the car's paint to a mirror finish. "Within a few days, arriving at my house was the CB Performance 2387cc turbocharged power-house, outfitted with their newest prototype programmable electronic fuel injection. Working with Pat Dormady at Tune-Rite Auto Service in my hometown at Oaksville, we massaged-in the wide-bodied engine into the very tight confines of the Oval Window's engine compartment. "Right around this time, June 2nd, 2006 to be exact, my wife Charlene gave birth to our daughter, Alexandra. So my schedule become more regimented - help out at home until about 10:00 pm, then head to the shop and work until 3:00 am, every night until the engine was in, and back together. I plumbed the oil lines, mounted the oil cooler, ran the rear fuel lines into the boost sensitive fuel pressure regulator, fit the tin, manifolds, and throttle bodies, connected the wiring, and made it all look good. Tripp Cycle machined a hair off the bottom of the passenger-side manifold, so it would tilt in a bit so clearancing the body for the pressure hat was not needed. I mounted the computer under the driver's side of the back seat, as well as the Optima red-top battery (in a stainless steel battery box made by Rob Roctman of Utah) under the passenger side of the back seat. Pat then bled the brakes and finished a few odds and ends for me, before we fired the mill for the first time, on June 23rd, at 6:00 pm. Man, was it a nice sounding motor, and I couldn't wait to see how it would run at the dragstrip. "My first showing of this car was the next day, at Toronto Motorsports Park in Cayuga, Ontario, for one of my sponsors - KC Auto Parts in St. Catharines. The following day was its debut at a VW show, the June Jitterbug. At this time, I still did not have the back seat in, or the carpet fitted. The back seat was recovered with tan vinyl to match the front buckets ('05 Driver FX), thanks to Auto Interiors by John. As soon as i picked up the seat, I finished the interior by installing the Sewfine door and rear panels, a Sewfine oatmeal loop carpet kit, and the back seat. Soon it was time to take a trip in July to Milan, Michigan for Bug-Out 21, where I entered the car show, and raced 1/8th-mile; I placed 2nd in class, and made it to Round 3 of eliminations, not too bad for the first time driving down the track. Then in August, we went to Indianapolis, Indiana, for the Volksbash event, where I got Best of Show, and raced 1/4-mile this time. I made it to three rounds again, and ran my best e.t. so far, a 12.28 at 105.22 miles per hour, at 15 lbs. of boost, on pump gas." Greg Stogren owns a very impressive looking, and running '56 sedan now, thanks to his dedication over the last 2 1/2 years seeing this project though. He thanks everyone already mentioned, but most of all pays special gratitude to his wife Charlene, and their daughter, Alexandria. With Greg's attention to detail, his next venture is a '59 Bug convertible, which we're sure will be just as nice or nicer than the Oval Window sunroof featured here. |